Inside robot joint motors, instead of using the electromagnetic pad brakes of the industrial mainstream, Elite Robot innovatively uses the electromagnetic pin brakes. This document will introduce the working principle of electromagnetic pin brake.

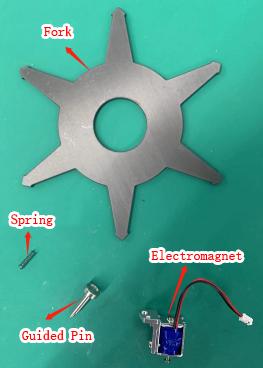

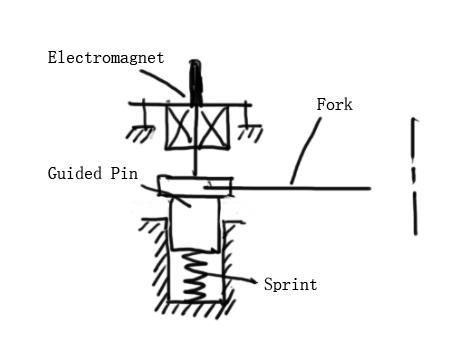

The snowflake-shaped fork is connected to the motor shaft. When the electromagnet is not powered, the guided pin is pushed up and blocks the fork, which holds the brake. If the electromagnet is powered, the guided pin will be pushed down by magnetic force and let go the fork, which release the brake.

The advantages of electromagnetic pin brakes over the electromagnetic pad brakes include:

The disadvantage of electromagnetic pin brakes is about the position of holding brake. After the robot is powered down, the robot joint has some movable range (60 degree/deceleration ratio). The robot arm might drop down a little big when after shutting down.