MOVE instructions are the new instructions of Elite EC series released with patch 3.4.1. MOVE instructions carries more parameters than MOV instructions. It cause users to spend more than on configuring carried parameters, but this parameters enables some applications that MOV instrucions cannot perform.

This article will introduce one of the most prominent applications: using the tool coordinate parameter or user coordinate parameter bound to MOVE instructions to apply the same program to multiple tasks under simular enviroment. For examples:

Note:

Applying the same program to different robot is a workable scenario with MOVEL or MOVEC instruction based programs. As transfering the program from robot A to robot B, the user just need to update the corresponding user coordinate on robot B, then the program is ready to run. Robot B can even be different model from robot A as long as both robots are EC series and points in the program are reachable for robot B.

An simple practical example: a robot cell added a deburr machine for an additional process after the existing processes. The EC63 robot need to load and unload the product to the deburr machine, but the deburr machine is too far away from robot to reach. Therefore the EC63 robot is going to be replaced with EC66. As long as the original EC63 uses MOVEL for most part of the robot, then the user can save a lot of time for teaching. Update the user coordinate bound to these instructions will make MOVEL and MOVEC based instructions be ready to run, the user just need to check the other instruction and make addtional program for loading to and unloading from deburr machine.

Sample programming:

(Robot A used in the sample is EC63 and robot B is EC66)

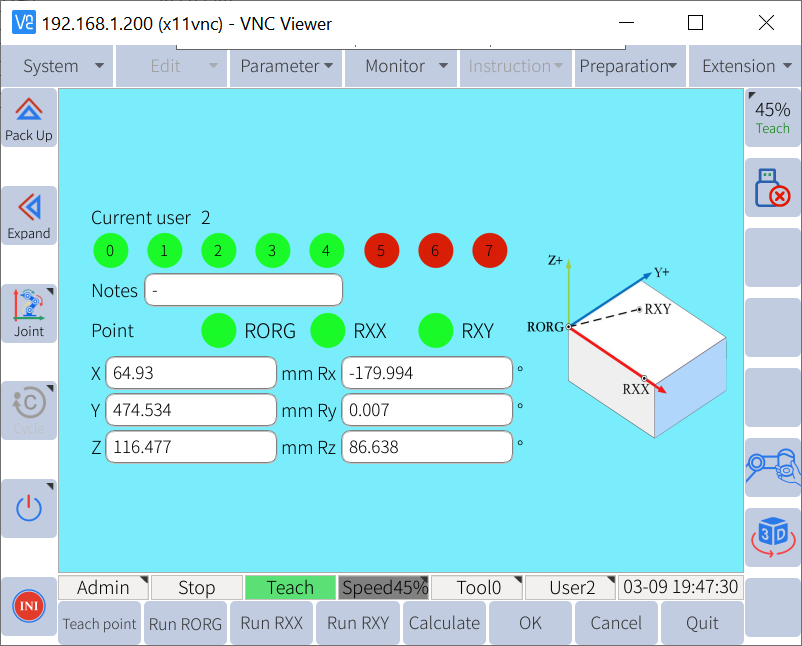

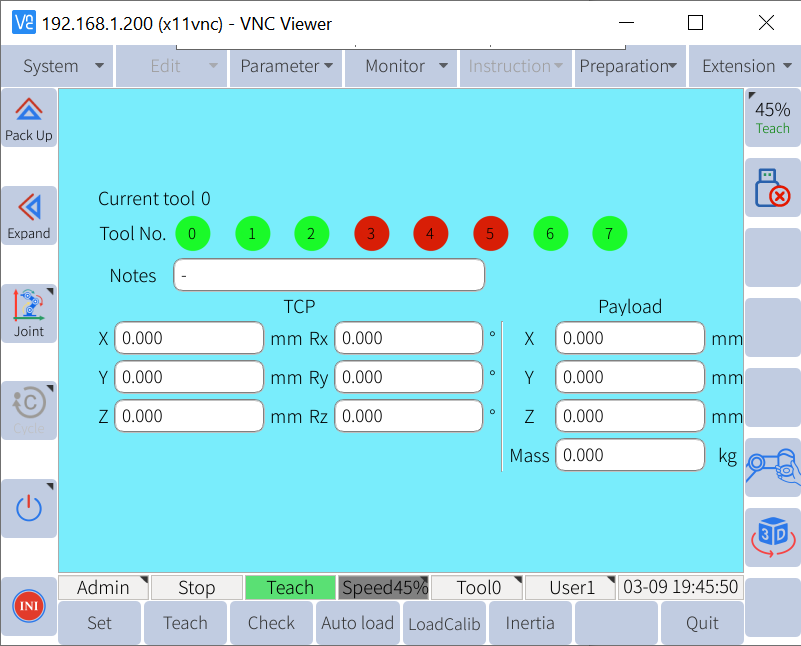

1. Edit the tool coordinates and user coordinates on robot A.

Figure 1. Configuration of User Coordianate 1 on Robot A

Figure 2. Configuration of Tool Coordianate 0 on Robot A

2. Robot A uses MOVEL and MOVEC instructions with V class variables. ConstV is recommended, so variables doesn't need to be copied while transfer the program. These instructions binds tool coordiante 0 and user coordinate 1. Note that ConstP cannot be used for positions, because P variables are absolute positions, which will not change with the change of bound user coordiantes and tool coordiantes.

NOP MOVEL ConstV=[13.4572936,64.5010677,-0.0027210,0.0078861,0.0000520,-2.3994709] V=200.0 CR=0.0MM ACC=50 DEC=50 USER#(1) REF=[-12.179,-57.905,100.426,-132.972,90.000,0.000] MOVEC ConstV=[89.5285196,101.5955984,0.0022078,0.0078655,0.0000483,-2.4052486] ConstV=[62.8384523,17.1893780,0.0071623,0.0078606,0.0000589,-2.4115739] V=200.0 CR=0.0MM ACC=50 DEC=50 USER#(1) REF=[-11.486,-68.343,117.973,-140.079,90.000,-0.001] MOVEL ConstV=[58.8814184,64.8581670,-0.0008410,0.0079104,0.0000527,-2.4821567] V=200.0 CR=0.0MM ACC=50 DEC=50 USER#(1) REF=[-7.441,-61.129,106.016,-135.340,90.000,0.000] MOVEL ConstV=[13.4552266,64.4998623,-0.0048271,0.0078995,0.0000519,-2.3994588] V=200.0 CR=0.0MM ACC=50 DEC=50 USER#(1) REF=[-12.179,-57.905,100.426,-132.973,90.000,0.000] END

Code 1. Program on robot A

3. Transfer the program from robot A to robot B with a USB. Configure the tool coordinate and user coordinate on robot B. It's recommended to use same coordinate ID, so parameters of the MOVE instructions wouldn't need modification. If the coordinate ID are different, the coordinate parameter of the MOVE instructions need to be updated as well.

Figure 3. Configuration of User Coordianate 2 on Robot B

Figure 4. Configuration of Tool Coordianate 0 on Robot B

NOP MOVEL ConstV=[13.4572936,64.5010677,-0.0027210,0.0078861,0.0000520,-2.3994709] V=200.0 CR=0.0MM ACC=50 DEC=50 USER#(2) REF=[-12.179,-57.905,100.426,-132.972,90.000,0.000] MOVEC ConstV=[89.5285196,101.5955984,0.0022078,0.0078655,0.0000483,-2.4052486] ConstV=[62.8384523,17.1893780,0.0071623,0.0078606,0.0000589,-2.4115739] V=200.0 CR=0.0MM ACC=50 DEC=50 USER#(2) REF=[-11.486,-68.343,117.973,-140.079,90.000,-0.001] MOVEL ConstV=[58.8814184,64.8581670,-0.0008410,0.0079104,0.0000527,-2.4821567] V=200.0 CR=0.0MM ACC=50 DEC=50 USER#(2) REF=[-7.441,-61.129,106.016,-135.340,90.000,0.000] MOVEL ConstV=[13.4552266,64.4998623,-0.0048271,0.0078995,0.0000519,-2.3994588] V=200.0 CR=0.0MM ACC=50 DEC=50 USER#(2) REF=[-12.179,-57.905,100.426,-132.973,90.000,0.000] END

Code 2. Program on robot B(Only User Coordnate # are modified)

4. Simply test whether there are errors. If there are errors, please correct the coordinate system.